Interior Doors

Millennium Doors

Millennium Doors

DOORMERICA _-_The_Millennium_Collection.[…]

Adobe Acrobat document [10.1 MB]

DOORMERICA is a manufacturer of quality door products. Operating Three state of the art manufacturing divisions serving the entire nation. The Millennium Collection featuring decorative wood composite doors, The American Series architectural and residential flush doors, and the Architectural Components interior aluminum frame division.

Strategically Located manufacturing plants in Atlanta Georgia, Sacramento and Stockton California provide dependable lead times and high quality products.

We are LEED certified and feature many products that meet green building initiatives. DOORMERICA is your full service commercial and residential door supplier, building quality products since 1989.

Jeldwen

Jeldwen Interior Wood Doors

jw-authentic-wood-doors-brochure.pdf

Adobe Acrobat document [5.7 MB]

Jeldwen Custom Interior Wood Doors

jw-custom-wood-interior-doors-brochure.p[…]

Adobe Acrobat document [7.0 MB]

A Footprint that Inspires Confidence

JELD-WEN is one of the world’s leading manufacturers of reliable windows and doors. Our extensive product offering encompasses windows, exterior doors, interior doors and related building products that are sold globally through multiple distribution channels, including retail home centers, wholesale distributors and building products dealers.

Consistently ranked as Oregon’s largest privately owned company, JELD-WEN began in 1960 as a small Oregon millwork plant with 15 employees and today has approximately 20,000 employees across more than 100 locations in the Americas, Europe, Asia and Australia. These strategically located facilities aim to serve their localities to best accommodate regional preferences and standards, and help minimize resources and costs required for transportation.

Only JELD-WEN has AuraLast®

JELD-WEN’s secret to longer-lasting wood windows and doors is an exclusive manufacturing process that protects against wood rot, water saturation, and termites. This process is how we make AuraLast Wood. Unlike dip-treated wood, which is common in the industry, JELD-WEN’s vacuum pressure process forces the protective ingredients all the way through to the core of the wood for virtually 100% penetration. We use a closed-loop, water-based system, which reduces volatile organic chemicals (VOCs) by 96% compared to the ordinary method of dip-treating wood in open vats of petroleum-based fluids. Our intense, vacuum pressure process also results in using less preservative to achieve an even greater level of effectiveness. The reliability of AuraLast wood is only available at JELD-WEN.

We Have You Covered

In addition to revolutionizing the wood window and door market with AuraLast wood, you can count on JELD-WEN for:

- World class service before, during and after a sale

- Industry-leading warranties

- Short lead times and on-time, accurate orders

- A knowledgeable network of dealers

- Experienced Architectural Consultants and Commercial Solutions Team

Continuous Improvement

Employees are dedicated to furnishing you with reliable windows and doors that deliver years of beautiful dependability. Our goal is that every product made is a promise kept. Employees are empowered to continuously improve products, customer service, and manufacturing excellence through our Superior Performance Program which is a framework for employees to submit ideas and participate in the implementation of their ideas.

Giving Back

JELD-WEN has been active in the communities where company operations exist. In 1969, the company began making contributions to the JELD-WEN Foundation, a non-profit organization whose mission is to enhance the communities where JELD-WEN employees live. In the U.S., the JELD-WEN Foundation contributes to the United Way, which provides college scholarships and grants for worthwhile community projects.

Woodgrain

Woodgrain Doors is one of the world’s leading manufacturers and suppliers of hardwood and softwood stile and rail doors, and door components. Distributors, builders, remodelers, architects and homeowners rely on Woodgrain products to build quality homes. Woodgrain is committed to innovation through continuous improvements in manufacturing, investment in design, excellence in craftsmanship and use of the highest quality raw materials to build doors that are as durable as they are beautiful.

- 60 years of excellence in the millwork and home building industry

- Largest manufacturer and supplier of pine doors in the world

- Unsurpassed quality craftsmanship

- All products come from renewable resources, using 99% of the tree

Woodgrain has manufactured millwork and building products for the residential and commercial construction markets since it was founded in 1954. Woodgrain Doors began in 1985 with the acquisition of Meridian Wood Products by our parent company, Woodgrain Millwork. Woodgrain Doors is headquartered in Nampa, Idaho and manufactures and distributes thousands of doors annually.

Woodgrain is a vertically integrated company that is family owned and operated. In its 60-year history, the company has expanded with millwork, distribution, doors and window divisions – making Woodgrain the preferred leader in the construction and home building industry. With our long standing excellence in millwork manufacturing, Woodgrain has grown to be one of the largest millwork companies in the world.

Woodgrain Doors’ mission is to be a market leader in wood stile and rail interior and exterior doors in North America by leading the industry with design innovation, manufacturing excellence and exceptional quality. We plan to achieve this by providing our customers exceptional value for commodity and specialized wood interior and exterior doors and millwork.

In our total commitment to the environment, Woodgrain promises to act as a responsible corporate citizen, optimizing our use of resources and producing products that have a positive impact on the environment and the health of people.

The wood used by Woodgrain primarily originates from sustainable sources. Over 99% of the wood fiber processed by Woodgrain is used as a product. Woodgrain recycles every product possible and strives to operate in an environmentally conscious manner.

In addition to our commitment to providing “best in class” solutions to our partners and their customers, Woodgrain Millwork is dedicated to social responsibility. At Woodgrain, we believe we have a role to play in strengthening the communities in which we do business. Over the years, Woodgrain and our employees have supported a wide variety of organizations through volunteer work, financial contribution and leadership. Employees are encouraged to get involved and give to their local organizations and charities whenever possible.

We responsibly manage and thoroughly evaluate Woodgrain’s environmental influences and their consequences. This includes being mindful of our stewardship as a leading corporation in a natural resource-dependent industry.

Simpson

Simpson has been making doors within the forests of Washington state since 1912. Generations of families have dedicated their lives to creating the finest doors in America. It’s a team effort requiring creativity, engineering, innovation and experience. So when you choose a Simpson door, you are not only getting a finely handcrafted piece for your home, you are getting a part of our home as well.

Simpson’s comprehensive line of interior and exterior stile and rail doors includes hundreds of standard options from panel to French to decorative entry doors with matching sidelights and transoms. Available in a variety of wood species, sizes and glass options, Simpson provides customers with the door they desire, whether it is a standard design or a one-of-a-kind custom door.

To learn more about Simpson’s history, please visit Simpson Investment Company.

We Are Proud of Our Doors.

Over a century ago, we set out to make doors that homeowners would be proud to call their own. But before we could do that, the doors had to first exceed our expectations. Today, that pride takes many forms, from our total commitment to safety to our reputation as pioneers of new products to creating doors with the quality our customers have depended on for decades. And that pride also takes shape in our commitment to natural resources and our environment.

Our Environmental Policy

The Simpson Family of Companies have a long, proud history of research and innovation. We have been pioneers in sustainable forestry and were early and enthusiastic supporters of the Sustainable Forestry Initiative® (SFI®). Simpson affiliates have earned high praise for their groundbreaking habitat conservation plans for protecting fish and wildlife and were the first private landowners in the country to successfully develop and implement a plan for the Northern Spotted Owl in California.

These works are based on some fundamental principles that make up our environmental policy:

- Foster a beyond-compliance philosophy in our business such that operations achieve or exceed all applicable environmental laws and regulations.

- Make environmental considerations a priority in operating existing facilities and planning new ones.

- Set meaningful, measurable goals for environmental performance and implement environmental management systems that track progress toward these goals.

- Minimize effects on the environment and work to continuously improve environmental performance through practices such as pollution prevention and resource conservation.

- Educate our employees on their responsibilities for environmental compliance and management.

- Certify that our fiber and wood purchasing practices foster sustainable forest management and the wise use of America’s most abundant renewable resource.

- Regularly review and update our environmental performance and management systems.

Fully Renewable Resource

We’re honored to work with such a resource as wood. An extraordinary building material, no alternative comes close to its abilities to conserve energy and address global climate change. Further, wood is naturally renewable as the resource is continually growing. Net annual growth for the nation’s commercial forests exceeds harvests and losses to insects and disease by an impressive 50 percent each year.Our Daily Commitment

Nature gives us an incredible resource to work with and we are conscientious to do everything we can to manufacture a product that is efficient, avoids waste and diminishes pollutants.

We purchase raw lumber and door components from responsible and reliable suppliers that subscribe to sound forest management practices, many of which are certified by a third party. We can also make doors with virtually unlimited choices of wood species.

We make the most of the natural resource in our manufacturing processes. Simpson was the first national stile and rail door manufacturer to move to engineered stiles and rails as a standard practice. This type of construction allows us to use the most of our resources and results in stronger, more stable components for our doors. And, wood waste is used as fuel for powering equipment at our facilities.

Simpson doors have no added urea-formaldehyde (NAUF), which minimizes potential pollutants and improves indoor air quality. Further, Simpson doors are CARB (California Air Resource Board) Phase 2 Compliant and have received certification of the lowest possible emissions of formaldehyde in a wood based product for volatile organic compounds (VOCs).*

* The 4-star certification comes from the Japanese Ministry of Land, Infrastructure and Transportation, one of the first international agencies to require VOC testing.Wood advantages:

- No other commonly used building material requires as little energy to produce as wood.

- Wood is resistant to heat, frost, corrosion and pollution.

- Using wood products reduces the need to burn fossil fuels for concrete and steel-based products, which reduces the amount of greenhouse gases released into the atmosphere.

- Wood removes pollutants from the air, rather than emitting them, sequestering greenhouse gases.

- Wood is an efficient insulator because its cellular structure contains air pockets that limit its ability to conduct heat.

Our Work Continues

We are strong supporters of third-party certification and green building programs. Their efforts have elevated home and building product design and development. And as the parameters of these programs are fine-tuned over time, we applaud those that include a lifecycle assessment as part of their evaluation.

Our manufacturing and purchasing practices are continually reviewed and improved to meet the changing needs of the market and our natural environment. But what has remained nearly unchanged for decades is our core policy to do more in respect to the world around us. And that’s something we are very proud of.

Masonite

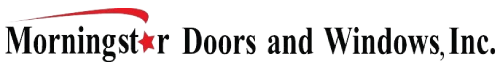

Premium solid core doors

Made with more recycled material than our standard hollow core doors, solid core interior doors enhance durability throughout a home. Increased density also reduces noise, creating quieter spaces for everyone.

See, feel and hear the difference

With 70% more sound-dampening material than our standard hollow core doors, solid core doors can help you create quieter spaces throughout the home. They’re a sound decision — and a whole lot more.

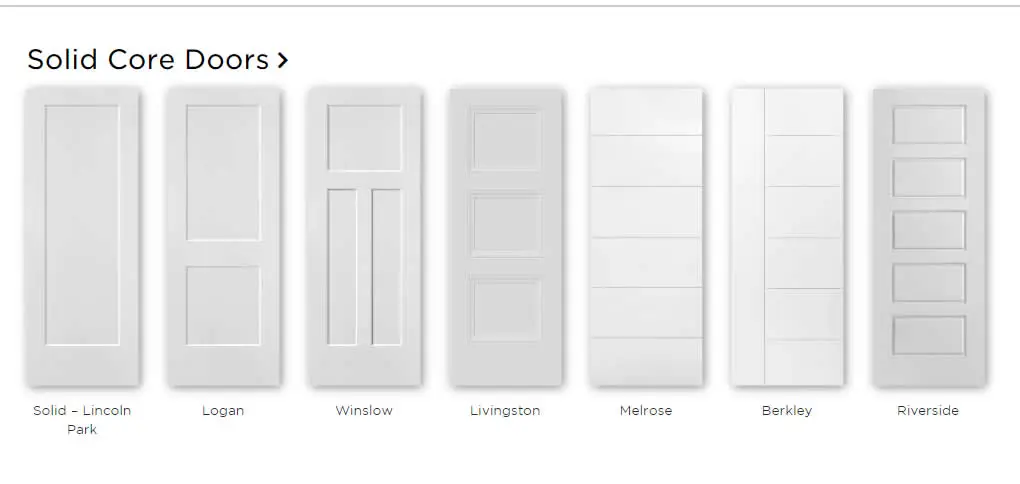

Custom and Quick-Ship Custom Steel Glass Doors, Steel Glass Walls

Glenview Doors

FINEST QUALITY OF WELDING CRAFTMANSHIP COMBINED WITH HIGH QUALITY OF EUROPEAN STEEL

Glenview Doors manufacturers finest collection of custom interior steel glass doors and offers several in-stock interior steel glass doors. In addition, custom steel glass walls are available as perfect solution to divide rooms. Steel glass doors and steel glass diving walls are crafted with narrow stile and rails which are perfect for homes with modern, contemporary and transition styles of architecture.

Steel glass interior doors provide a timeless minimalist design for residential projects like condos, single family homes, home offices and for large variety of commercial offices, hotels and restaurants. Our steel glass interior doors and steel glass walls complement various architectural styles including industrial, modern, contemporary, traditional, and transitional. The narrow stile and rail profiles can only be accomplished with steel materials and deliver a very elegant and minimalistic look which cannot be matched by doors made from other materials.

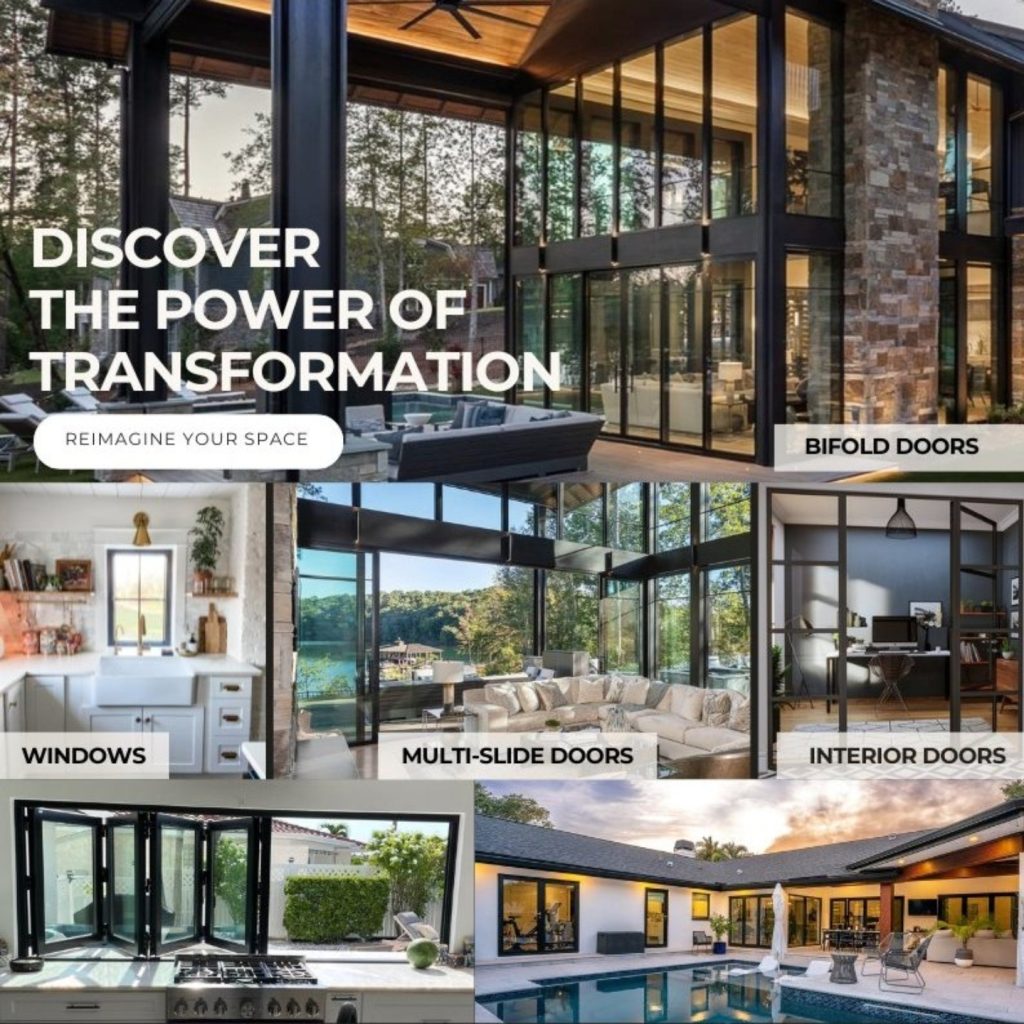

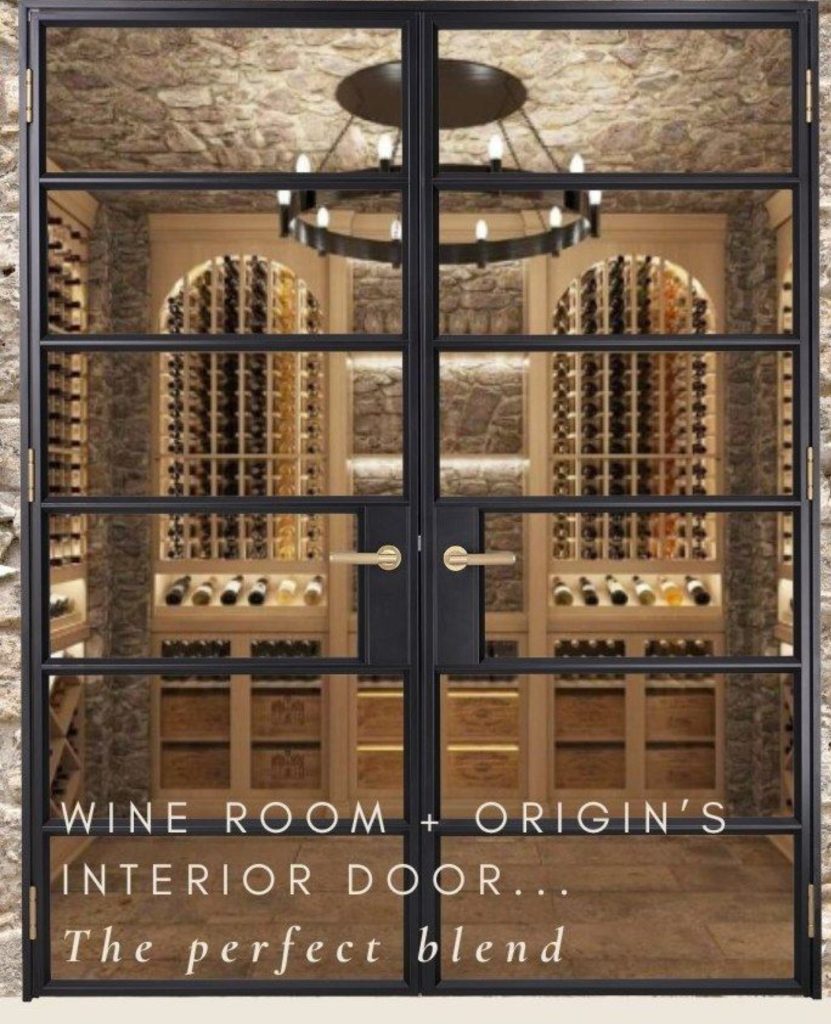

Origin Doors and Windows

Origin’s Internal Door range is a product collection that contains single doors, French doors and fixed screens that can be used in home and commercial environments. By using a steel-look aluminum, it is perfect for dividing out spaces to make a property far more functional while allowing light to flow through effortlessly.

Completely customizable, choose your size, color, configuration and glazing bar style, and allow Origin to create a stunning solution that will revolutionize your interior design. It offers the unique ability to provide privacy and noise distraction whilst allowing an openness in design to be achieved. With a sightline of just over 1″, its sleek design ensures all property styles are complemented.

Glass Options

The Internal Door can accommodate different styles of glass which maximizes its versatility. Clear glass ensures light can flow unhindered, whilst the likes of reeded or frosted glass means the OI-30 can be used in rooms where privacy is needed – perhaps a boardroom in a commercial environment or even in a utility or bathroom in a home.

Lock Options

OI-30 Doors can be specified with either a handle only or with a thumb turn option which will lock the door in place. This locking option again adds to its versatility of rooms it’s able to be used in. The handle itself sits on a lock block which is placed on the middle glazing panel. Alternatively, the lock block can run the entire height of the door.

Configurations

Available in 100’s of RAL colors, the OI-30 can be specified in a variety of configurations such as Single Doors, French Doors, Fixed Screens and Corner configurations. Choose your door and screen set up and combine it with a corner post to create an entire new room in your space. This option is perfect for creating the likes of breakout rooms or new Boardrooms in an office.

Fixed screens can also be added to the tops or side of door configurations to really maximize the space and create a remarkable spectacle.

Glazing Bars

The OI-30 allows you to customize how many glazing bars you want on your door. These can be installed horizontally, vertically or both.

By using more or creating a grid effect, you will be able to achieve a more traditional or heritage look for your door or screen. For a more modern, minimalist or contemporary style, fewer bars should be used. This allows light to really flow through whilst not serving practical benefits of being able to shut out places.

Two different bead options are available too – square or chamfered – which can be used to further enhance a modern or traditional style.

if you have any questions please let me know, thanks

Upgrade Your Home With Simpson’s Finely Crafted Interior and Exterior Stile and Rail Doors.

Address

215 Adams Blvd. Farmingdale, NY 11735

More Links

© 2024 Morningstar Doors and Windows, Inc